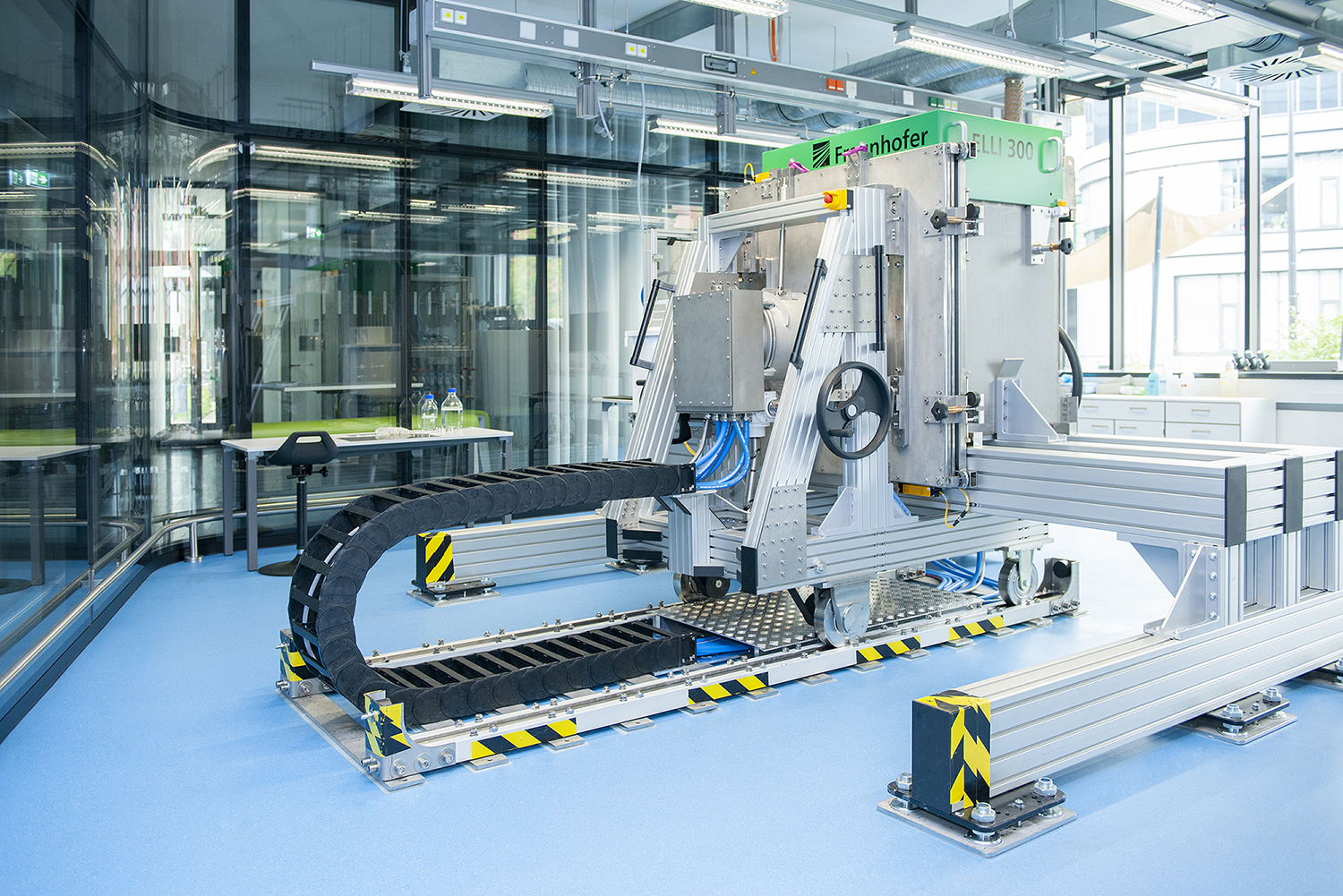

Pilot Plant for the Industrial-Scale Production of Safe and Effective Vaccines installed at the Fraunhofer Institute for Cell Therapy and Immunology (Fraunhofer IZI) in Leipzig

In August 2018, a pilot plant for low-energy electron irradiation of liquids was installed and commissioned at Fraunhofer IZI in Leipzig. This plant is designed to contribute to scaling up an innovative procedure for inactivating viruses and other pathogens from laboratory to industrial scale.

With precise control, electrons can be useful in many fields of industries. They are activated with a high level of precision to ensure that the depth of penetration into certain media can be accurately adjusted. However, so far, the uniform irradiation of liquid media, such as those used in the production of vaccines, has constituted a major challenge. Now, scientists at the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology (FEP) have succeeded in effectively treating liquids with electrons in compact plants.

This development constitutes an important milestone in the framework of a joint project of the IZI, FEP, IGB and IPA Fraunhofer Institutes. Together, these four institutes are developing a procedure for the inactivation of viruses and other pathogens based on low-energy electron irradiation with the aim of the safer, more effective and, in addition, more cost-efficient production of vaccines.

The effectiveness of this method has already been comprehensively tested and demonstrated with the help of various viruses, bacteria and parasites in a lab scale at Fraunhofer IZI and Fraunhofer IGB. In order ensure the suitability of the results for industrial use, Fraunhofer FEP and IPA have developed a sophisticated plant concept for continuous liquid treatment. At this plant, pathogens can now be treated with the required target dose in a controlled manner.

With the development of the automated process module, Fraunhofer Institute for Manufacturing Engineering and Automation (IPA) has contributed to ensuring that the inactivation technology can easily be scaled up and transferred to industrial use. This process does not only permit the treatment of bigger volumes of liquid, but the safe handling of biologically active liquids has now also reached a level relevant for industries. In August 2018, the pilot plant was successfully installed and commissioned in a biosafety level 3 lab at the Fraunhofer Institute in Leipzig.

The project was supported by the Bill & Melinda Gates Foundation, which contributed USD 1.85 million (Grant Agreement Investment ID: OPP1154635).